Yc-8101a Mai Zafi Mai Zafi Ba Tare Da Mannewa Ba Nano-composite Ceramic Rufin Nano (Baƙi)

Abubuwan da aka haɗa da samfurin da kuma bayyanarsa

(Rufin yumbu mai sassa biyu)

YC-8101A-A:Shafi na A shafi

YC-8101A-B: Maganin magance sinadaran B

Launuka na YC-8101:haske, ja, rawaya, shuɗi, fari, da sauransu. Ana iya yin daidaita launi bisa ga buƙatun abokin ciniki

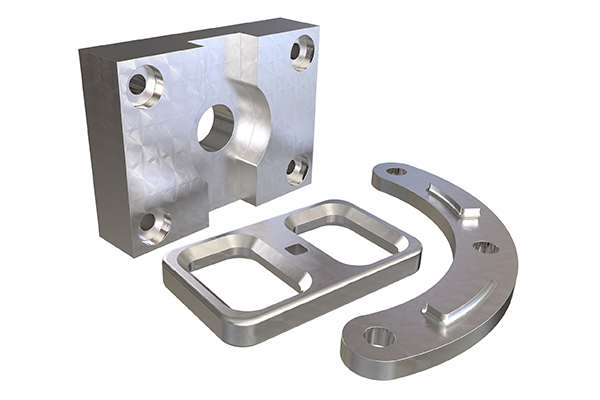

Substrate mai dacewa

Ana iya yin saman abubuwa daban-daban kamar kwanoni marasa mannewa da ƙarfe, ƙarfe mai laushi, ƙarfe mai carbon, bakin ƙarfe, ƙarfe mai aluminum, ƙarfe mai titanium, ƙarfe mai yawan zafin jiki, gilashin microcrystalline, yumbu, da sauran ƙarfe.

Zafin jiki mai dacewa

- Matsakaicin juriyar zafin jiki shine 800℃, kuma zafin aiki na dogon lokaci yana cikin 600℃. Yana da juriya ga zaizayar ƙasa kai tsaye ta hanyar harshen wuta ko kwararar iskar gas mai zafi.

- Juriyar zafin shafi zai bambanta dangane da juriyar zafin da ke tattare da nau'ikan substrates daban-daban. Yana jure sanyi da zafi da girgizar zafi.

Siffofin samfurin

- 1. Rufin Nano-coatings an yi su ne kawai da ruwa, ba su da haɗari, ba sa cutar da muhalli kuma ba sa cutar da muhalli.

- 2. Tukwane masu hade da Nano suna samun haske mai yawa da santsi a ƙaramin zafin jiki na 250℃, wanda ke adana kuzari kuma yana da kyau.

- 3. Juriyar sinadarai: Juriyar zafi, juriyar acid, juriyar alkali, kariya daga zafi, juriya ga kayayyakin sinadarai, da sauransu.

- 4. Rufin yana da juriya ga yanayin zafi mai yawa da girgizar zafi a cikin wani kauri (kimanin microns 30), kuma yana da juriya mai kyau ga girgizar zafi (mai juriya ga musayar zafi, kuma baya fashewa ko barewa a lokacin rayuwar rufin).

- 5. Rufin nano-inorganic yana da kauri kuma yana da ingantaccen aikin rufin lantarki, tare da ƙarfin juriyar rufi na kimanin volts 1000.

- 6. Yana da ingantaccen yanayin zafi da kuma ƙarfin haɗin kai mai kyau.

- 7. Tauri: 9H, yana jure wa harshen wuta mai buɗewa da yanayin zafi mai yawa har zuwa digiri 400, mai sheƙi sosai, da kuma juriyar lalacewa mai yawa

Filayen aikace-aikace

1. Abubuwan da ke cikin tukunyar jirgi, bututu, bawuloli, masu musayar zafi, radiators;

2. Gilashin microcrystalline, kayan aiki da kayan aiki, na'urorin likitanci, kayan aikin magunguna, da kayan aikin kwayoyin halitta;

3. Na'urori masu zafin jiki mai yawa da kayan firikwensin masu zafin jiki mai yawa;

4. Sassan kayan aikin ƙarfe, molds, da kayan aikin siminti;

5. Abubuwan dumama wutar lantarki, tankuna, da akwatuna;

6. Ƙananan kayan gida, kayan kicin, da sauransu.

7. Abubuwan da ke da zafi mai yawa ga masana'antun sinadarai da ƙarfe.

Hanyar amfani

(Domin tabbatar da sakamako mai kyau, ana ba da shawarar a yi amfani da shi ta wannan hanyar)

1. Bangare biyu:Rufe kuma a tace a cikin rabon nauyi na 2:1 na tsawon awanni 2 zuwa 3. Sannan a tace murfin da aka warke ta hanyar allon tacewa mai kauri 400. Rufin da aka tace ya zama murfin yumbu mai hade da nano kuma an ajiye shi a gefe don amfani daga baya. Ya kamata a yi amfani da fenti na sauran cikin awanni 24; in ba haka ba, aikin sa zai ragu ko ya taurare.

2. Tsaftace kayan tushe:Rage mai da kuma cire tsatsa, rage girman saman da kuma lalata yashi, da kuma lalata yashi da darajar Sa2.5 ko sama da haka, ana samun mafi kyawun sakamako ta hanyar lalata yashi da corundum mai raga 46 (farin corundum).

3. Zafin yin burodi: 270℃ na tsawon mintuna 30 (Ana iya warkewa a zafin ɗaki. Aikin farko bai yi kyau ba, amma zai iya komawa yadda yake a kan lokaci.)

4. Hanyar gini Fesawa:Ya kamata a sanyaya kayan aikin da za a fesa a wuta zuwa zafin da ya kai digiri 40 kafin a fesa; in ba haka ba, za a iya yin lanƙwasa ko raguwa. Ana ba da shawarar cewa kauri na fesawa ya kasance cikin microns 30. Ana iya fesawa sau ɗaya kawai.

5. Maganin kayan shafa da maganin shafawa

Gudanar da kayan shafa: A tsaftace sosai da ethanol mai ruwa, a busar da shi da iska mai matsewa sannan a adana shi.

6. Maganin shafawa: Bayan fesawa, a bar shi ya bushe a saman na tsawon minti 30. Sannan a sanya shi a cikin tanda da aka saita a digiri 250 sannan a bar shi ya yi zafi na minti 30. Bayan ya huce, a cire shi.

Musamman ga Youcai

1. Kwanciyar hankali ta fasaha

Bayan gwaji mai tsauri, tsarin fasahar yumbu na nanocomposite na sararin samaniya ya kasance mai karko a ƙarƙashin yanayi mai tsauri, yana jure yanayin zafi mai yawa, girgizar zafi da kuma lalata sinadarai.

2. Fasahar watsawa ta Nano

Tsarin watsawa na musamman yana tabbatar da cewa ƙwayoyin halittar suna yaɗuwa daidai gwargwado a cikin murfin, yana guje wa haɗuwa. Ingantaccen maganin haɗin gwiwa yana haɓaka haɗin tsakanin ƙwayoyin halitta, yana inganta ƙarfin haɗin gwiwa tsakanin murfin da substrate da kuma cikakken aikin.

3. Ikon sarrafa shafi

Daidaitattun tsare-tsare da dabarun haɗaka suna ba da damar aikin shafa ya zama mai daidaitawa, kamar tauri, juriya ga lalacewa da kwanciyar hankali na zafi, wanda ke biyan buƙatun aikace-aikace daban-daban.

4. Sifofin tsarin ƙananan nano:

Barbashin yumbu na Nanocomposite suna naɗe barbashin micrometer, suna cike gibin, suna samar da wani abu mai kauri, kuma suna ƙara ƙanƙantawa da juriya ga tsatsa. A halin yanzu, ƙananan barbashi suna ratsa saman substrate, suna samar da wani ƙarfe-yumbu mai haɗin gwiwa, wanda ke ƙara ƙarfin haɗin gwiwa da ƙarfi gaba ɗaya.

Ka'idar Bincike da Ci gaba

1. Matsalar daidaita faɗaɗa zafin jiki:Yawan faɗaɗa zafi na ƙarfe da kayan yumbu sau da yawa ya bambanta a lokacin dumama da sanyaya. Wannan na iya haifar da samuwar ƙananan fasa a cikin murfin yayin zagayowar zafin jiki, ko ma barewa. Don magance wannan matsalar, Youcai ta ƙirƙiro sabbin kayan shafa waɗanda yawan faɗaɗa zafi ya fi kusa da na ƙarfen, ta haka ne za a rage damuwa ta zafi.

2. Juriya ga girgizar zafi da girgizar zafi: Idan murfin saman ƙarfe ya sauya cikin sauri tsakanin zafi mai yawa da ƙasa, dole ne ya iya jure wa matsin lamba na zafi da ya haifar ba tare da lalacewa ba. Wannan yana buƙatar murfin ya sami kyakkyawan juriyar girgizar zafi. Ta hanyar inganta tsarin murfin, kamar ƙara yawan hanyoyin haɗin lokaci da rage girman hatsi, Youcai zai iya ƙara juriyar girgizar zafi.

3. Ƙarfin ɗaurewa: Ƙarfin haɗin da ke tsakanin murfin da ƙarfe yana da matuƙar muhimmanci ga dorewar murfin na dogon lokaci da dorewa. Don haɓaka ƙarfin haɗin gwiwa, Youcai ya gabatar da wani Layer na tsaka-tsaki ko Layer na canzawa tsakanin murfin da substrate don inganta danshi da haɗin sinadarai tsakanin su biyun.